Custom Hanger Design Services

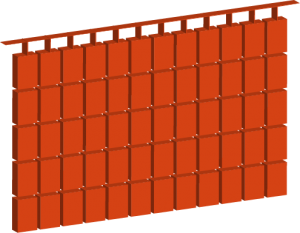

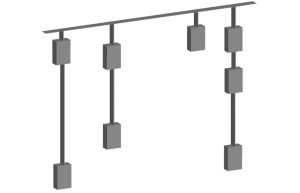

In addition to our 200 meters long and 2.1 meters high automatic production line, we are able to manufacture custom hangers even for your very challenging products.

Utilising our technical knowledge and know-how of racking, we are able to build custom hangers for the challenging products you might have.

Does your company produce custom shaped pieces that have been difficult to powder coat? With us, You don’t have to worry about that.

We work closely with Mansen Metalli, a machine shop owned by the same family who owns Linjateräs. From Mansen Metalli we can order customized hangers for you quickly and easily.

Therefore, we are able to suspend and powder coat even a very wide range of challenging parts, competitively and efficiently.

vs.

Our Hanger Technology Saves You Money.

Efficiently 2.1 meters high and 200 meters long, our continuously running automatic powder coating production line enables dense and efficient racking of your products, and guarantees consistent quality and cost-effectiveness. It doesn’t only save your money, but also the environment.

Powder coating is a durable, cost-effective and eye-catching way to finish your product

Powder coating is the highest quality coating method, especially for metals. We’ve developed a modernized powder coating system with 7-phase pretreatment process and realtime status monitoring.

The powder-coated surface is also an environmentally sustainable solution and will remain good for up to 50 years.

Powder coating is an environmentally friendly choice

We care about our carbon footprint, materials and how we use them.

Powder coatings do not use chlorinated hydrocarbons or organic solvents at all, thus avoiding VOC emissions that pollute the atmosphere with volatile gases. In addition, we collect the paint residue and reuse it – our paint use rate is almost 100%.

We have also developed a better way of packaging and make more environmentally friendly material choices. On top of all this, we have built a foam index that allows us to compare the amount of foam used to the painted track meters. We also have the ISO 14001: 2015 environmental certificate.

Are You Interested?

We’ve got all your powder coating needs covered.

What you should take into consideration when preparing your product for powder coating?

The powder coating finishes the surface of your product beautifully. However, it does not fix and fill the shapes of your product. In other words, if your product has possible surface unevenness or other imperfections, the powder coating will not be able to fix them. So always remember to prepare and finish your product carefully for painting. For example, if your product has visible unfinished welds or any other imperfections before the powder coating, they will still be visible after the powder coating.

The Future of Your Product Begins Here

Linjateräs