Powder Coating Process and Materials

Personal and professional service and our continuously running 200 meter long automatic powder coating production line guarantee you reliable and efficient operation every time.

Up to 6,000 m2 of finished paint surface per day with our process

We serve you in three shifts and can paint up to 6,000 m2 of finished surface per day. Our new service workshop enables worry-free purchases and more peace of mind for you.

The Steps of Our Powder Coating Process

- Quality Control and Suspension

- Pretreatment

- Drying

- Powder Coating

- Baking

- Quality Inspection

- Packaging

- Shipping

1. Quality Control and Racking

Before placing the products on our hanger system, we inspect their quality. After the quality check, we hang your products on the powder coating production line. Our 200-meter and 2.1-meter-high continuous automatic production line allows tight and efficient racking.

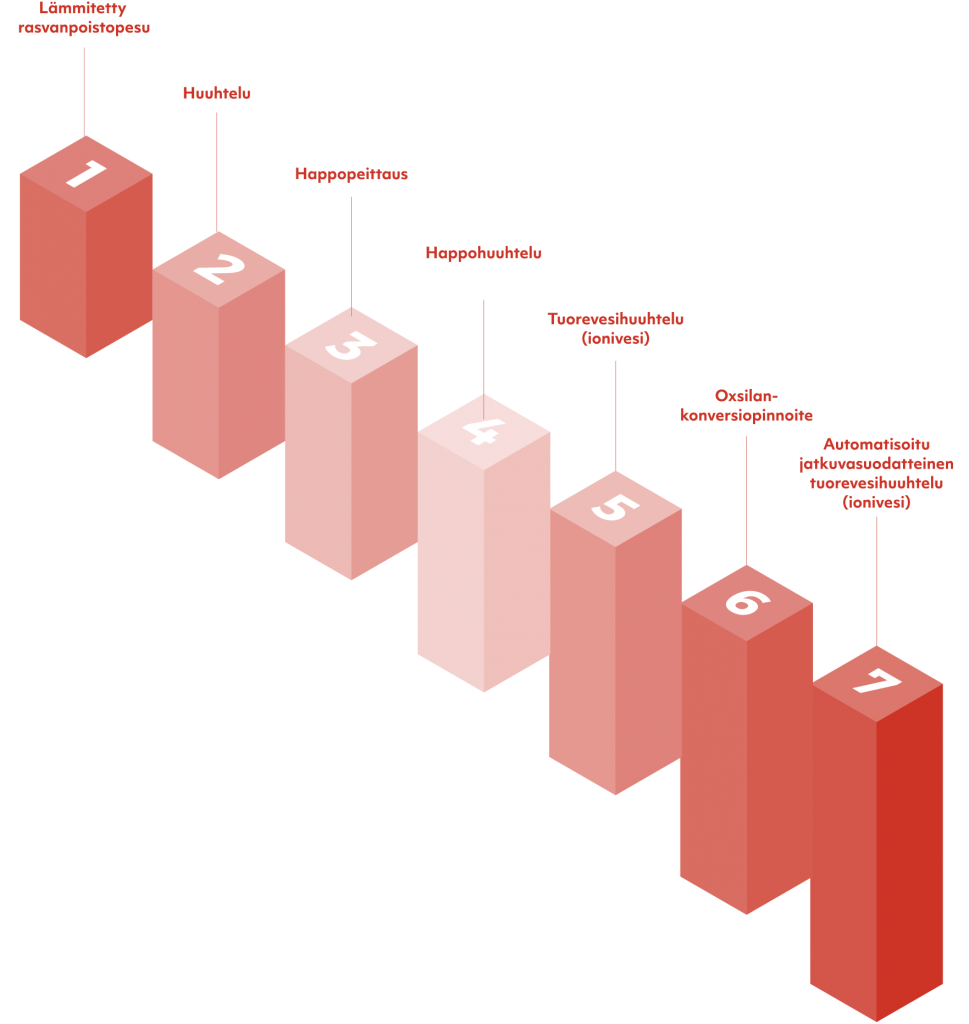

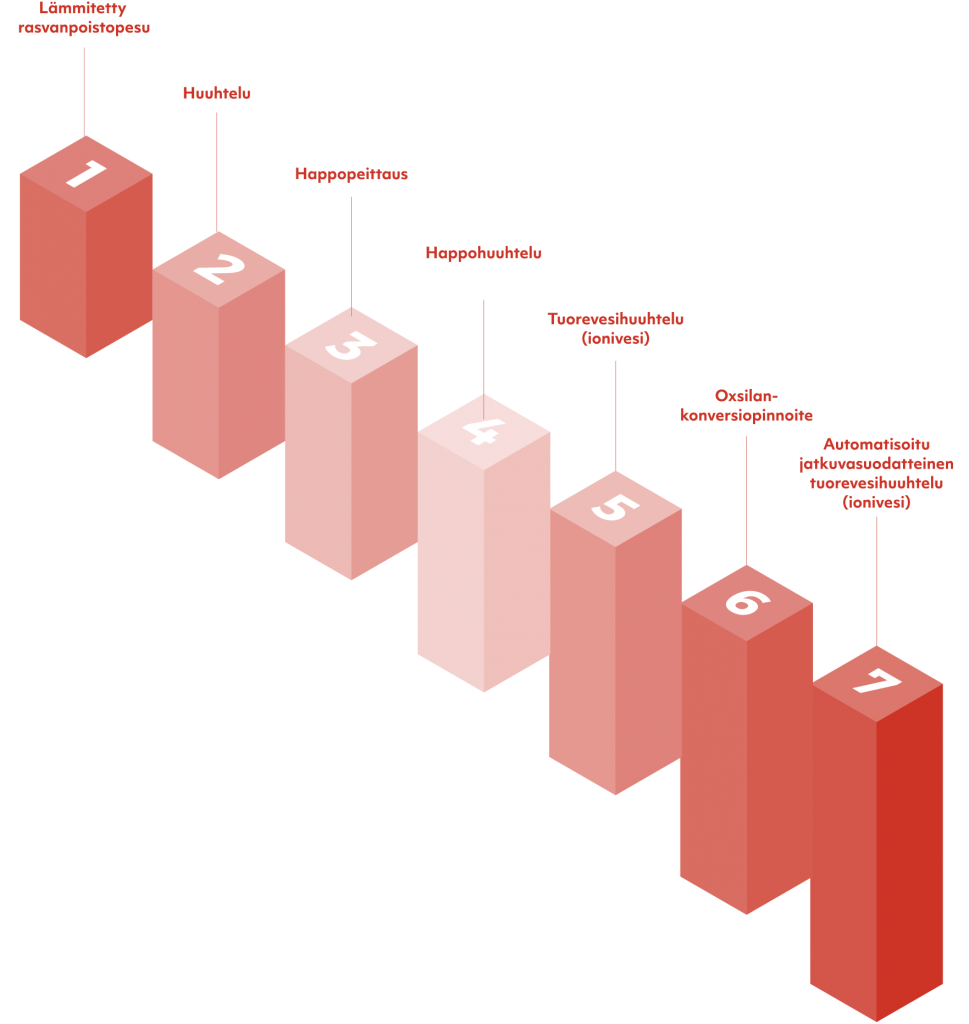

2. 7-stage pretreatment in a 65 meter long washing tunnel

The quality of the powder coated surface is already done in the pre-treatment phase. Our revolutionary 65-meter, 7-stage, pre-treatment production line prepares your product for powder coating in a never before seen way in this industry. Great pre-treatment guarantees the durability of the paint surface.

Pre – treatment steps

3. Drying

Water on the surface of the product causes the powder coating to boil. Therefore, after the pre-treatment phases, your product ends up in a state-of-the-art 20-meter long drying oven that dries the parts to be painted very carefully for painting.

4. Powder coating in an automatic painting cabinet

The powder coating paints used for painting metal surfaces are sprayed on the surface and painted using compressed air.

Our powder coating cabinet is completely custom-made for us and designed together with VTT (one of Europe’s leading research institutions), It enables e.g. Finland’s fastest color changes.

Our automatic powder coating cabinet paints with precision and, if necessary, our painter completes the powder coating of your product(s) by hand.

5. Polymerization of the paint, ie baking in a powder oven

The typical parameters of our 30-meter baking oven are 160-220 degrees / 20-30 minutes.

Electrostatics fix the paint, and after the oven, the paint surface becomes very wear and shock resistant. Any scratches or abrasions that may occur later during the installation phase of your product can be easily removed with car wax or fine water-based sandpaper and wax.

6. Quality Inspection

We inspect the overall and visual quality of the product, as well as, check the paint adhesion and measure the thickness of the paint film according to the customer’s wishes and selected the quality package. 8 different measurement methods are available. Afterwards, we’ll fill up the necessary quality control documents.

7. Packaging (and assembly)

The Packaging and finishing according to the customer’s instructions. As an additional service we offer, for example, thread opening and assembly.

8. Fast Shipping

You will receive your carefully finished product within 1-5 business days of its arrival to us.

As a VIP service, we also offer a Fast Track Service. Ask More.

The Steps of Our Powder Coating Process

1. Quality Control and Racking

Before placing the products on our hanger system, we inspect their quality. After the quality check, we hang your products on the powder coating production line. Our 200-meter and 2.1-meter-high continuous automatic production line allows tight and efficient racking.

2. 7-stage pretreatment in a 65 meter long washing tunnel

The quality of the powder coated surface is already done in the pre-treatment phase. Our revolutionary 65-meter, 7-stage, pre-treatment production line prepares your product for powder coating in a never before seen way in this industry. Great pre-treatment guarantees the durability of the paint surface.

Pretreatment

3. Drying

Water on the surface of the product causes the powder coating to boil. Therefore, after the pre-treatment phases, your product ends up in a state-of-the-art 20-meter long drying oven that dries the parts to be painted very carefully for painting.

4. Powder coating in an automatic painting cabinet

The powder coating paints used for painting metal surfaces are sprayed on the surface and painted using compressed air.

Our powder coating cabinet is completely custom-made for us and designed together with VTT (one of Europe’s leading research institutions), It enables e.g. Finland’s fastest color changes.

Our automatic powder coating cabinet paints with precision and, if necessary, our painter completes the powder coating of your product(s) by hand.

5. Polymerization of the paint, ie baking in a powder oven

The typical parameters of our 30-meter baking oven are 160-220 degrees / 20-30 minutes.

Electrostatics fix the paint, and after the oven, the paint surface becomes very wear and shock resistant. Any scratches or abrasions that may occur later during the installation phase of your product can be easily removed with car wax or fine water-based sandpaper and wax.

6. Quality Inspection

We inspect the overall and visual quality of the product, as well as, check the paint adhesion and measure the thickness of the paint film according to the customer’s wishes and selected the quality package. 8 different measurement methods are available. Afterwards, we’ll fill up the necessary quality control documents.

7. Packaging (and assembly)

The Packaging and finishing according to the customer’s instructions. As an additional service we offer, for example, thread opening and assembly.

8. Fast Shipping

You will receive your carefully finished product within 1-5 business days of its arrival to us.

As a VIP service, we also offer a Fast Track Service. Ask More.

We will help you choose the best powder paint for your application

The powder paint is always selected according to the application. Severe climatic conditions and harsh physical or chemical stress naturally have stricter requirements on the powder coating than clean interior use, for example.

Our professional staff are always happy to help you choose the right powder coating for you application, as well as answer questions about color availability and matching, and more.

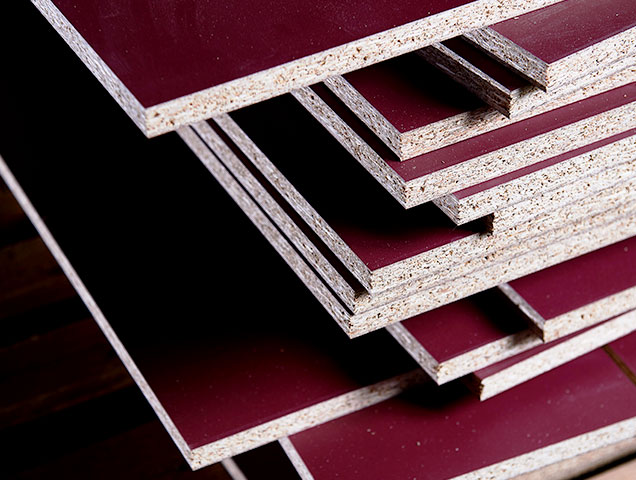

We paint all the most common metals and other surfaces

Powder coating is best suited for metals such as steel, aluminum and galvanized steel (including hot-dip galvanized steel). However, thanks to the advanced technology in the field, it is also possible to paint other surfaces with certain reservations.

Steel

Steel is a popular and fully recyclable material, but is corroded by oxygen and moisture. Therefore, it should be protected from rust. Stainless steel is especially suitable as a material for wet and humid conditions. Due to its weather resistance, it is a popular material for facades, for example.

Aluminium

Aluminium is more expensive but significantly lighter than stainless steel. It is thus a common material, especially in the construction industry and vehicles. Typical applications include wall and window structures as well as glazed structures, facades and coverings, wall panels and partitions, ventilation and heating equipment, and boats, ships, trains, cars, bicycles, airplanes, and space shuttles.

Galvanized Steel

(also HDG)

Zinc-plated a.k.a. galvanised steel is a cheaper material than stainless steel. However, it is less shiny or even on the surface and is more challenging to clean. Powder coating improves the appearance of the zinc coating. In addition, powder coating extends the life of galvanized steel – which of course applies to all materials to be painted.

Hot-dip galvanized steel is resistant to salt water, so it is commonly used especially in the ship building industry. Other applications include street poles and railings and fences.

Other Materials

The Modern technology also makes it possible to powder paint multidimensional objects. With certain reservations, we can powder paint wood, plastic and composite products.

Maximum dimensions of the powder coated product:

Width: 1 150 mm | Height: 2 100 mm | Length: 6 600 mm (even 9 100mm with certain reservations)

The most common binders for powder paints

EPOXY POWDER

Epoxy powders are suitable for paint coatings in the metal industry for products stored indoors that require chemical resistance, such as resistance to acids and alkalines. Epoxy powders are well suited for special applications in the heavy metal and chemical industries.

EPOXY POLYESTER POWDERS

Epoxy polyester powders are best suited for interior applications that require mechanical strength. Epoxy polyester powders are also a cost-effective choice, as their short paint time is also reflected in the price.

POLYESTER POWDERS

Polyester powder is a very common powder paint as it is suitable for both indoor and outdoor use. Polyester powders are suitable for use e.g. in the metal industry product painting for outdoor applications where good weather resistance and yellowing resistance to heat and UV light are required. For demanding conditions, a corrosion-resistant painting system in accordance with the standard SFS-EN ISO 12944-2 environmental classification is selected.

POLYURETHANE POWDER

Polyurethane powders are suitable for products whose surface must be highly resistant to mechanical and chemical wear. Polyurethane powders have good UV protection, which means that they are ideal for outdoor applications. Applications can be, for example, forestry and field machines, bicycles and other vehicles. They are also used in anti-graffiti paints.

Special Paints

ANTIBACTERIAL PAINTS

Bacteria and microbes on the surface of the antibacterial paint are quickly destroyed. A surface treated with antibacterial paint passes even the strictest hygiene level criteria, and thus common applications include kitchens, hospitals, laboratories and other research facilities.

ANTI-GRAFFITI PAINTS

nti-graffiti paints are very resistant to even strong solvents without damaging the paint surface. Therefore, they are used in areas where it is desired to facilitate the cleaning of potential stains.

SUPER DURABLE PAINTS

Super Durable powder coatings are extremely resistant to weathering, UV radiation and mechanical wear, among other things. These powder coatings are therefore well suited for the construction industry, (play) parks and fences, as well as the ship, train and automotive industries.

LACQUERS

Powder lacquers are also available in color.

HEAT RESISTANT PAINTS (SILICONE PAINTS)

Silicone powders are used in products whose coatings must withstand higher than normal temperatures. Typical applications are, for example, heaters, grills, exhaust pipes and fireplaces.

PRIMERS, ZINC AND EPOXY PRIMERS

Zinc improves corrosion resistance. Zinc-based primers are especially suitable for applications whose long life cycle could otherwise be shortened by harsh climates.

ELECTRODUCTIVE POWDER PAINTS (ESD)

Electrically conductive or ESD powder paints are antistatic and are especially suitable for areas where static electricity can cause problems. ESD paints are used in the electronics industry, for example.

Surface Qualities

HAMMER PAINT

Hammer paint is a special metallic lacquer paint suitable for indoor and outdoor use, which is also suitable for wood surfaces with reservations. The hammer paint, as the name implies, forms a surface that conforms to hammered enamel and is highly resistant to corrosion.

STRUCTURAL PAINTS (SAND PAPER AND ORANGE EFFECT)

Structural paints give interesting effects to the surface. They are suitable for both outdoor and indoor use and are commonly used in electronic products and furniture, among other things.

METAL AND PEARL PAINTS

The range of metallic and pearlescent paints is comprehensive. Ask for more details.

Gloss Levels

Glossy 85-95%

Semi-gloss 65-80%

Matte 20-30%

Supermatt 1-5%

Almost all gloss levels are possible when made separately.

A Wide Range of Colors

Lots of different color options

RAL and RR colors (mainly in stock)

NCS and other special colors

Pearl and structural surfaces

If you wish, we will find out the color matches.

Monitor the status of your product from our customer portal

Accurate metering and monitoring follows and tracks your product at every stage. When your product arrives to us, it is registered in our system. You can follow the status of your product from our customer portal in real time. With the help of accurate video tracking, we can check how our product has been processed and treated up to 2 months back, if necessary.

Are You Interested?

We’ll powder coat your products beautifully and efficiently.

What you should consider when preparing your product for powder coating?

The powder coating finishes the surface of your product beautifully. However, it does not fix and fill the shapes of your product. In other words, if your product has possible surface unevenness or other imperfections, the powder coating will not be able to fix them. So always remember to prepare and finish your product carefully for painting. For example, if your product has visible unfinished welds or any other imperfections before the powder coating, they will still be visible after the powder coating.

The Future of Your Product Begins Here

Linjateräs Oy